Cascia

Cascia

Cascia is dedicated to advancing the field of stem cell therapies into the clinic by embracing proven technological improvements, and this includes the use of reactive artificial intelligence. Our main initiative in this respect is AccelThera, our computerized workflow solution for preparing cellular preparations that are customized to each patient and their immediate therapeutic needs. AccelThera exchanges information with medical instrumentation, processing equipment, and testing devices to ensure that the complex calculations required for each batch are done properly and in accordance with our quality standards.

Cascia is dedicated to advancing the field of stem cell therapies into the clinic by embracing proven technological improvements, and this includes the use of reactive artificial intelligence. Our main initiative in this respect is AccelThera, our computerized workflow solution for preparing cellular preparations that are customized to each patient and their immediate therapeutic needs. AccelThera exchanges information with medical instrumentation, processing equipment, and testing devices to ensure that the complex calculations required for each batch are done properly and in accordance with our quality standards.

Image recognition of cell products for quality control and to identify rare phenotypes. We routinely use flow cytometry analysis to inspect a sample of the cell product that we are going to send to the operating room, and the instrument captures a microscopic image of thousands of cells as they pass through the detector. This provides both improved quality control and allows us to capture images for training future algorithms.

Image recognition of cell products for quality control and to identify rare phenotypes. We routinely use flow cytometry analysis to inspect a sample of the cell product that we are going to send to the operating room, and the instrument captures a microscopic image of thousands of cells as they pass through the detector. This provides both improved quality control and allows us to capture images for training future algorithms.

Biometrics allow our technicians and medical scientists to interact with technology without physically interacting with the equipment. Voice commands, transmitted via headsets, substitute for the use of keyboards that might spread pathogens, and use of facial and iris recognition protects our computing resources and limites physical access to our offices, research laboratories, and processing centers.

Biometrics allow our technicians and medical scientists to interact with technology without physically interacting with the equipment. Voice commands, transmitted via headsets, substitute for the use of keyboards that might spread pathogens, and use of facial and iris recognition protects our computing resources and limites physical access to our offices, research laboratories, and processing centers.

IoT technology (the “Internet of Things”) enables us to maintain a consistent level of quality control across all of our locations. AccelThera interfaces with various monitoring devices in the processing center and operating room. IoT enabled equipment transmits telemetry reading periodically so that we can remotely track various equipment, parameters such as schedule maintenance time or temperature excursions of our refrigeration units during a power failure.

IoT technology (the “Internet of Things”) enables us to maintain a consistent level of quality control across all of our locations. AccelThera interfaces with various monitoring devices in the processing center and operating room. IoT enabled equipment transmits telemetry reading periodically so that we can remotely track various equipment, parameters such as schedule maintenance time or temperature excursions of our refrigeration units during a power failure.

Photopolymerization of materials when constructing implants enables us to modulate the tensile strength and to program the period of resorbtion. These parameters affect how the cells behave after they are transplanted into the patient, but the optimal wavelength to use and the desired, laser pulse energy is specific to each patient.

Photopolymerization of materials when constructing implants enables us to modulate the tensile strength and to program the period of resorbtion. These parameters affect how the cells behave after they are transplanted into the patient, but the optimal wavelength to use and the desired, laser pulse energy is specific to each patient.

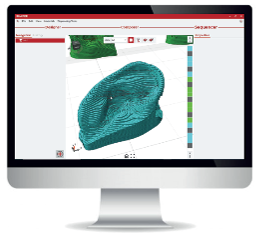

Designing implants to repair hard tissues can be accomplished by 3D modeling software that is part of our bioprinting solution. The software allows us to import DICOM (Digital Imaging and Communications in Medicine) files from MRI, CT scans, or X ray machines, and convert them to stereolithography commands for use in the bioprinter.

Designing implants to repair hard tissues can be accomplished by 3D modeling software that is part of our bioprinting solution. The software allows us to import DICOM (Digital Imaging and Communications in Medicine) files from MRI, CT scans, or X ray machines, and convert them to stereolithography commands for use in the bioprinter.